Start

About Pharmec

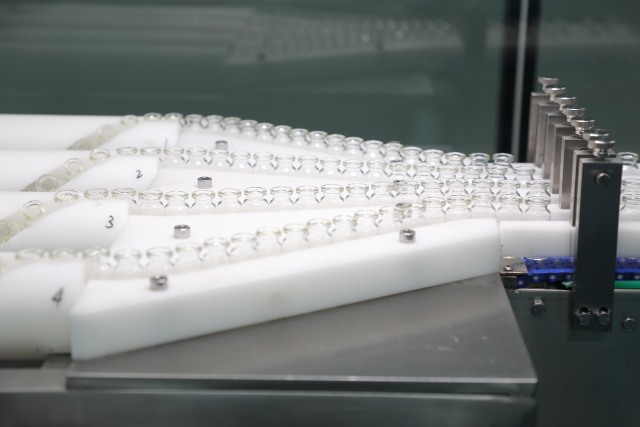

Our Solutions

Our Service

Our Products

Our Case

News

Contact Us

| Model | PT-120-A | PT-300-B |

| Spec. | Antibiotic Vials 5ml~100ml | |

| Productivity | 1000- 7200pcs/h | 6000- 18000pcs/h |

| Power | 96 KW | 160 KW |

| Net Weight | 8000kg | 9000kg |

| Dimension | 20000*5000*2600mm | 28000*5000*2600mm |