Start

About Pharmec

Our Solutions

Our Service

Our Products

Our Case

News

Contact Us

|

Model

|

PT-APS3

|

|

Specification

|

0.2ml-20ml

|

|

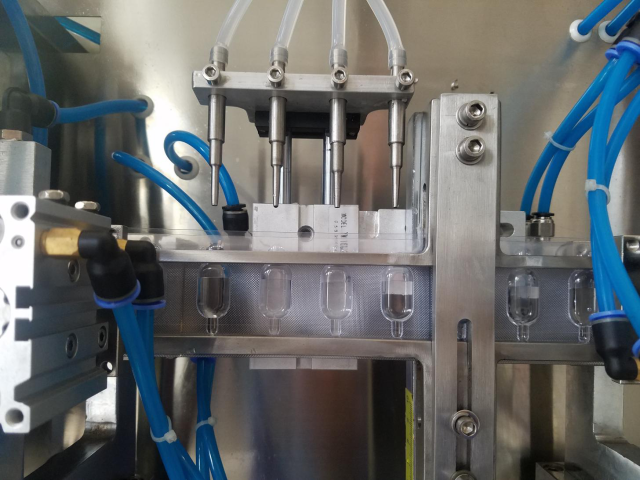

Mould Cavity

|

3×7

|

|

Product weight deviation

|

±0.08g

|

|

Qualified rate

|

99.50%

|

|

Filling accuracy

|

±5%

|

|

Boundary dimension

|

6200mm×3100mm×2730mm(L×W×H)

|

|

Working weight of equipment

|

About 13000Kg

|

|

Installed power

|

100kw,50HZ,380V,3 phase 5 lines

|

|

Working face height

|

1050±20mm

|

|

Filter brand

|

Cobetter

|

|

Cooling water

|

Flowrate: 2.5m³ /h

|

|

Pressure: 2.5 ~ 3.5bar

|

|

|

Temperature: 7-12℃(adjustable)

|

|

|

Compressed air

|

Flowrate: 40m³ /h

|

|

Pressure: 6 ~ 8bar

|

|

|

Vacuum

|

Flowrate: 63 m³/h

|

|

Pressure: -0.075MPa(min)

(the machine has been configured the vacuumsystem)

|

|

|

CIP/SIP inlet

|

Puresteam:2.7-3.4bar,40kg/h,125℃

|

|

Cleanliquid:2m³/h,2-3bar

|

|

|

Extrusion

|

LDPE:120 Kg/h

|

|

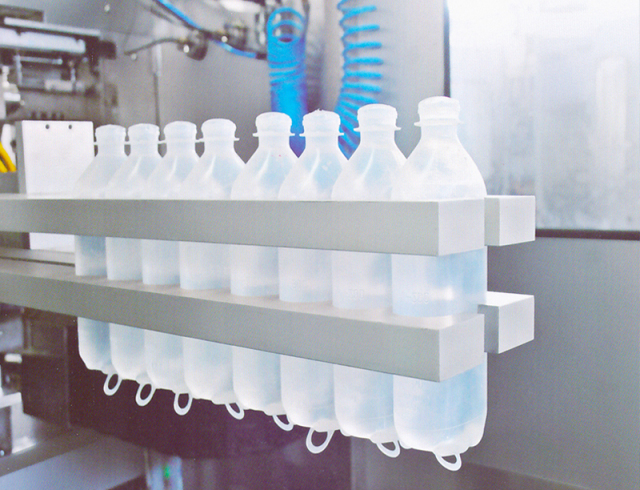

Suitable Sizes of bottle

|

The suitable scope of the machine: size1-20mL ampoule, it can be realized after adding relevant change parts(0.4-20mL). The Buyer

provide the samples or drawing, the related filling volume information.

|

|

Motion controller

|

Siemens Brand

|

|

MCGS

|

SCADA

|

|

HMI

|

15’ Siemens Brand

|