Start

About Pharmec

Our Solutions

Our Service

Our Products

Our Case

News

Contact Us

|

Model

|

PT-RSYG2-1-2500SC/ST

|

PT-RSYG2-2-3000

|

PT-RSYG4-1-5500SC/ST

|

PT-RST-Z1G2-800

|

PT-RST-Z2G4-1500

|

|

Output capacity

|

≥2,200 bags/hour for 100ml/250ml

≥2,000 bags/hour for 500ml

|

≥2,500 bags/hour

for 100ml ≥2,200 bags/hour

for 250ml ≥2,000 bags/hour

for 500ml |

≥4,300 bags/hour

for 100ml/250ml ≥4,000 bags/hour

for 500ml |

≥700 bags/hour for 2000ml

≥550 bags/hour for 3000ml

|

≥1,400 bags/hour for 2000ml

≥1,100 bags/hour for 3000ml

|

|

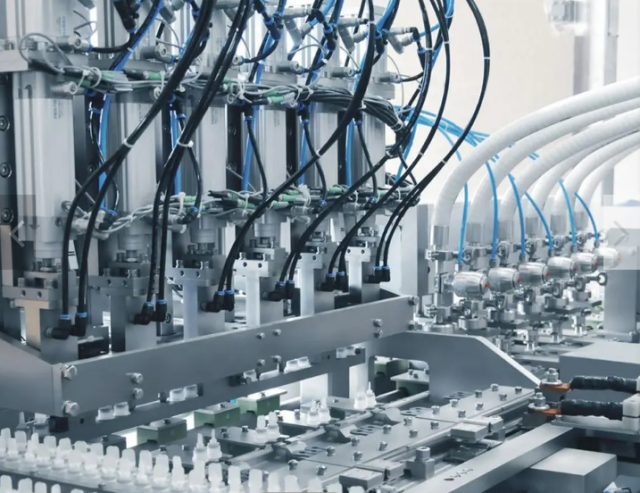

Filling accuracy

|

500ml: ±1%

250ml: ±1.5%

100ml: ±2%

|

±0.5%

|

|||

|

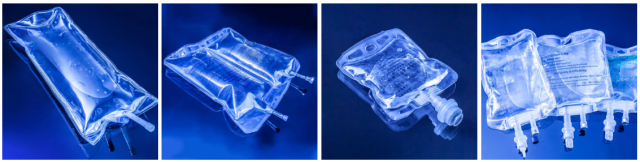

Production specification

|

Single-chamber bag: 50-500ml

|

Single-chamber bag: ≤3000ml

|

Single-chamber bag: 1000ml, 2000ml, 3000ml or other customized bag

|

||

|

Output of bags at a time

|

2

|

2

|

4

|

1

|

2

|

|

Working noise

|

About 75dB

|

||||

|

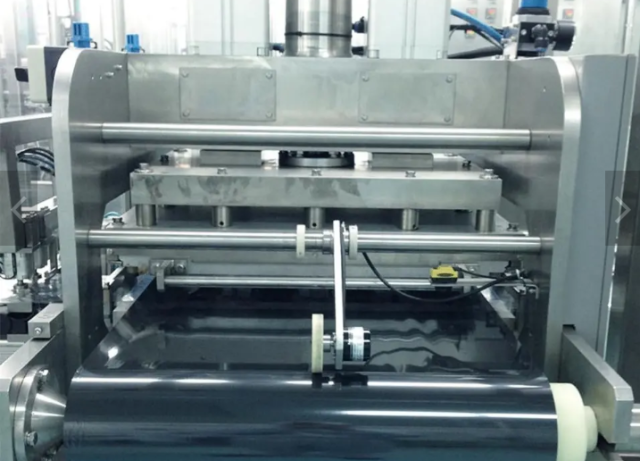

Inner diameter of ribbon

|

3 inches (76.2mm)

|

||||

|

Outer diameter of ribbon

|

Max. 140mm

|

||||

|

Inner diameter of film roll

|

6 feet (152.4mm)

|

||||

|

Outer diameter of film roll

|

Max. 600mm

|

||||

|

Printing

|

Hot press printing, single color

|

||||

|

Voltage

|

3×380V

|

||||

|

Power

|

32KW

|

18KW

|

32KW

|

22KW

|

28KW

|

|

Frequency

|

50Hz

|

||||

|

Machine size

|

6.5m×2.65m×2.0m

(LxWxH) |

5.8m×2.9m×2.0m

(LxWxH) |

9.2m×2.9m×2.1m

(LxWxH) |

7.1m×3.1m×2.0m

(LxWxH) |

11.3m×3.2m×2.3m

(LxWxH) |

|

Machine weight

|

7T

|

6.5T

|

9.5T

|

7.8T

|

11.8T

|